A camera lens is one of the most important components of photography, allowing us to capture everything from stunning landscape scenes to beautiful portraits. Have you ever wondered how such a complex piece of technology is created? Today, Mastersbuyorlease will take an in-depth look at how professional camera lenses are manufactured. From raw materials like glass and polycarbonate plastic through to final assembly steps, we’ll dive deep into all aspects of the process, so if you’ve ever wanted to find out more about what goes into making great lenses for your DSLRs, let’s figure out.

A camera lens is meticulously crafted by combining multiple glass elements in a precise arrangement to achieve the desired optical properties. These glass elements undergo intricate grinding and polishing processes to attain accurate shapes and sizes. Additionally, they are coated with carefully selected materials to minimize reflections and enhance the quality of the captured images.

What are camera lenses?

A camera lens is a curved piece of glass or other transparent material that uses refraction to bend light rays and focus them onto the camera’s image sensor. The shape, size, and quality of these lenses are critical in determining the overall image quality of a photograph. Different types of lenses are used for various photography purposes, including standard lenses, telephoto lenses, wide-angle lenses, and macro lenses. Each of these lenses has a unique design and construction to achieve specific photographic effects.

Lens Design

The lens design marks the critical initial phase in the process of creating optical lenses. During this phase, various lens specifications, such as focal length, aperture, and image quality, are meticulously determined. This intricate step is facilitated by specialized software that accurately simulates the behavior of light as it traverses through the lens, allowing for precise optimization and fine-tuning. By carefully considering these factors, designers can ensure optimal performance and desired characteristics in the final lens product.

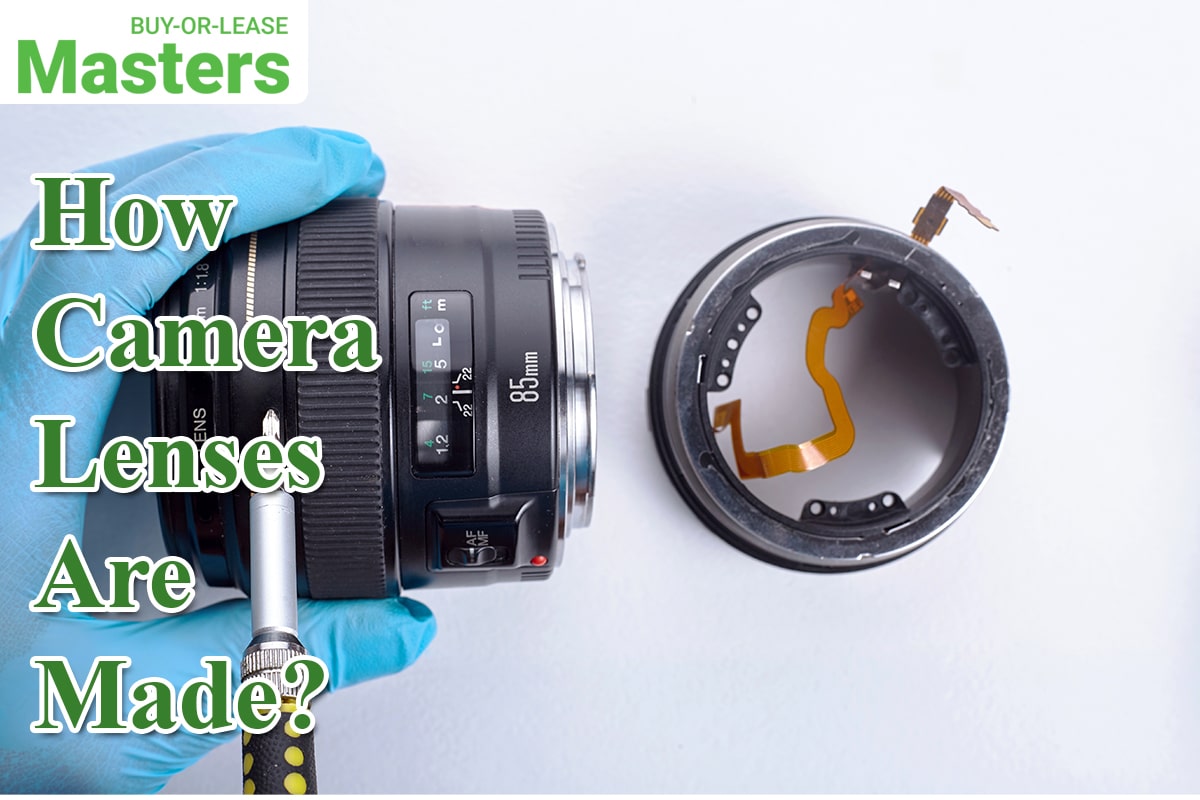

Once the lens design is meticulously finalized, the manufacturing process commences. Each lens element, carefully crafted from high-quality glass or durable plastic, undergoes precision grinding and polishing techniques to achieve optimal shape and smoothness. To ensure exceptional image quality and minimize unwanted glare, the surfaces of the lens elements are expertly coated with multiple layers of anti-reflective coatings, enhancing light transmission and reducing reflections.

Subsequently, the lens elements are meticulously assembled into a precisely engineered lens barrel. Crafted from a combination of robust metal or lightweight plastic, the barrel serves the crucial purpose of securely holding the lens elements in place while allowing for precise adjustments to the focus and aperture settings. Every detail is taken into consideration to create a lens that offers exceptional optical performance and versatility for photographers and videographers alike.

For example, many lenses feature internal focusing mechanisms that keep the lens’s length constant, making it easier to handle and reducing the chance of dust or debris entering the lens. Other design aspects such as weather sealing and vibration reduction technologies also play a vital role in creating durable and reliable lenses that can withstand any shooting conditions.

Create Glass Selection

The type of glass used in a lens greatly influences its performance and image quality. Manufacturers carefully select specific types of glass, such as optical crown or flint glass, based on their refractive index, dispersion properties, and resistance to temperature changes. These factors are crucial in determining the lens’s color fidelity, sharpness, and ability to minimize chromatic aberrations – unwanted color fringing that can occur in images.

Moreover, some lenses feature special glass elements, such as low-dispersion or extra-low dispersion (ED) glass, which help reduce chromatic aberrations even further. These high-quality glass materials require precise and careful handling during the manufacturing process to ensure their optical properties are not compromised.

Create Lens Coating

The coating process is an essential step in creating high-quality camera lenses. It involves applying multiple layers of anti-reflective coatings to the lens elements‘ surfaces. These coatings are carefully selected to minimize reflections and increase light transmission, resulting in sharper images with more accurate colors.

Apart from anti-reflective coatings, manufacturers also apply hydrophobic and oleophobic coatings to repel water, oils, and other contaminants that can easily affect image quality. By keeping the lens surface clean and free from smudges, photographers can capture clearer images without having to constantly clean their lenses.

Lens Manufacturing

Once all the lens elements are precisely crafted, coated, and assembled into a barrel, the final manufacturing process begins. This involves testing and fine-tuning the lens’s optical performance through various quality control tests, including resolution testing, distortion analysis, and color accuracy measurements.

The lenses also undergo rigorous field testing in different shooting conditions to ensure their durability and reliability. Any issues identified during this process are addressed, and the lenses undergo further improvements until they meet the manufacturer’s strict standards.

Final Thoughts

Knowing how complex and intricate the process of creating a camera lens is puts into perspective the laborious work that goes into constructing each lens. Every single element, from the grinding and polishing of glass elements to ensuring their precision measurements and wrapping them in carefully selected coatings requires intense skill and attention to detail. From raw materials to finished product, lens manufacturers have packed a lot of craftsmanship into constructing a high-quality camera lens.

Taking all of these facts into account, it’s no surprise that buying a good camera lens is an investment – one with numerous benefits and opportunities which can elevate your photography to the next level. Now that you know how cameras lenses are made, why not give it a try yourself? And once you’re done, don’t forget to leave a comment below!

Leave a Reply